Client Overview – Amara Raja Batteries

- Planvisage

- Nov 30, 2023

- 2 min read

Updated: Dec 1, 2023

Client Overview – Amara Raja Batteries

Amara Raja Batteries is a leading producer of auto and industrial batteries with turnover of

about USD 300 million. It has a tie up USA based Johnson Controls who have 26% stake in this company. It is one of the largest and most modern automotive battery plants in Asia with

installed capacity of 2.5 million batteries per annum. They make all the components required for battery and hence integrated backward in the supply chain.

Planvisage Solution

Amara Raja was in look out for a good planning and scheduling solution since 2006. They

evaluated solutions from Preactor and Rockwell before deciding to go ahead with solution from Planvisage. The implementation started in 2007 for both auto and industrial batteries division. The solution was integrated with their Ramco ERP. Main objective of the solution was to improve customer service level and maximize throughput.

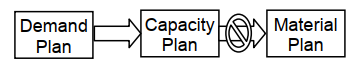

Planning before Planvisage

The marketing team generates the demand for next month with daily schedule. Based on this demand, the capacity plan is manually generated. While creating the capacity plan, no

check is made to see if the material is available or not. There is no link to purchase team of which order needs to expedited or de-expedited based on capacity plan. This was creating problem in execution as production cannot start due to lack of material which in turn affected optimum use of resource and customer delivery. There was no feedback to the marketing team on the commitment date based on material and capacity constraints. Since the supply chain was complex, the total planning time was more than a week.

Hence their planning frequency was once in a month.

Some of the issues with their planning process were

• End to end planning took about 10 days due to factory complexity and the process was

manual

• Planning frequency was once in a month. So any problems like delay from supplier,

machine breakdown, cycle time variation or material rejection, the effect was not know until

the next month.

• Unable to synchronize multiple departments. Plastic components capacity was shared

between auto and industrial batteries. There was no visibility of when the components will

be ready for assembly

• Unable to find the critical resource

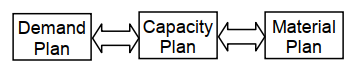

Planning After Planvisage

Based on the demand generated by marketing team, a single plan is created across multiple

department taking into account real time material and capacity constraints. A feedback is provided to the marketing on the commitment date of orders.

It helped Amara Raja in

• Providing advance visibility of which procurement orders have to be expedited / deexpedited based on capacity plan

• Planning frequency was made every day. So any problem like delay of supplier, machine breakdown, cycle time variation or material rejection, the effect was know the very next

day.

• Bottleneck resources are effectively loaded and thereby increased throughput.

Testimonials

"Earlier there was no feedback loop to marketing team on when the order will be delivered. Now with Planvisage solution, we are able to give continuous feedback to marketing team based on existing material and capacity constraints"

- Mr. Balaji Kiran, Chief Planner

"Our purchase schedule was not in line with customer schedule which caused us to miss the

due dates. Through backward planning in Planvisage, we are able to know which purchase

order needs to expedited / de-expedited based on demand and capacity loading"

- Mr. Damodar Rao, DGM SCM

Comments